Results 1 to 15 of 18

Thread: Block wall core fill problem.

-

29th April 2008, 07:19 PM #1

Novice

Novice

- Join Date

- Apr 2008

- Location

- QLD

- Posts

- 16

Block wall core fill problem.

Block wall core fill problem.

Hi all,

Im building a 2.6m block retaining wall soon & will have a builder mate do the concreting but i have to

organise the digging, steel etc ready for the concrete.

Im a sparky so im fairly new to this.

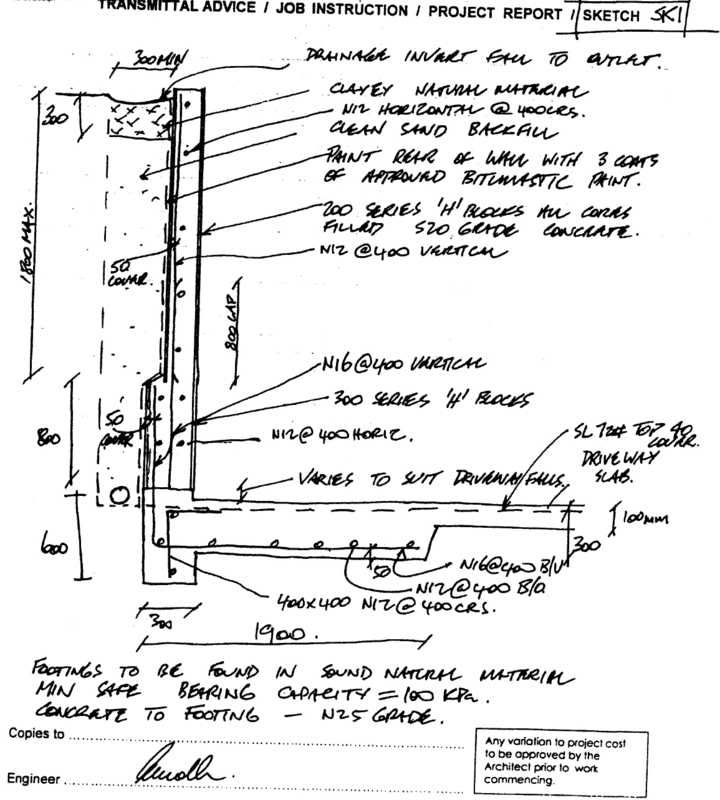

I have engineering drawings done although hand drawn so i have a couple of questions.

1800mm high is the max i can go with 200mm blocks so i have to use 300mm blocks 4 blocks high (courses?)

The problem i face is when i core fill it the concrete will spill out the rear 100mm of the uncovered

300mm block.

Someone suggested i core fill the 300mm blocks first before the brickie starts laying the 200mm blocks

on top but to me this sounds like the wall won't be as strong as there is a join between the upper &

lower core fills. If this is correct the 200mm blocks will only be strengthened by the vertical reo

@400. Is this ok ?

Or i thought i could have the brickie cover the open section behind the wall with flat blocks & core

fill the whole wall at the same time.....to me this will be stronger.

Also what does B/U & B/O mean when written after say N16@400 ?

Cheers.Last edited by DJ’s Timber; 29th April 2008 at 11:53 PM. Reason: Add drawing.

-

29th April 2008, 09:26 PM #2

I'll take a guess and say Bent Up and Bent Over.

The concrete core fill wont overflow through the open section of the 300 mm block as much as you might think. Maybe a little will come out but it is not going to keep pouring out. The blocks absorb the water in the core fill and a stiff plug of concrete forms fast. If you fill the wall lengthways (like it is supposed to be done) you pause when you've gone one course up higher than the 300 blocks.

-

29th April 2008, 11:38 PM #3

Novice

Novice

- Join Date

- Apr 2008

- Location

- QLD

- Posts

- 16

Hi DD,

I thought the mix would be quite liquidy & with 1.8m of head above it i recon it would spill out. Can only guess as i don't really know.

Anyway, for some reason my initial post has disappeared so i will re post the question again.

Cheers.

-

30th April 2008, 01:57 AM #4

Intermediate Member

Intermediate Member

- Join Date

- Aug 2007

- Location

- devonport

- Posts

- 26

Have been doing a few of these lately seem to be the latest in engineering design , I usually lay the 300s then place cement sheet (3.5mm) ripped down to 120 mm wide with a grinder on the back third of the block then lay the 200s on top of the 300s in line with the face so that the back of the block sits on the cement sheet with a thin layer of mortar and it caps off the rest of the 300 block . Most builders tend to think u need to concrete fill the 300s then lay the 200s till u explain this method which eliminates a cold joint , and all of a sudden they take ownership of the idea. cheers

-

30th April 2008, 01:59 AM #5

Intermediate Member

Intermediate Member

- Join Date

- Aug 2007

- Location

- devonport

- Posts

- 26

One other thing it also pays to cement a splay on top of the cement sheet with left over concrete or mortar prior to tanking to eliminate the edge where water may penetrate.

-

30th April 2008, 04:32 PM #6

Novice

Novice

- Join Date

- Apr 2008

- Location

- QLD

- Posts

- 16

"Cold joint", thats what its called hey.

Personally i don't like the idea of two separate core fills so i will talk to the bricky about your cement sheet idea. I can see that working well......cheers.

As for water proofing im going to seal the back of it with bitumastic paint.

If thats the case of only one pour then i wont need to do the two separate vertical reo bars with the n16 over lapping the n12 like in the drawing.

I should be able to drop down a 2.6m n16 bar after the block layer has gone. Might be cheaper, will find out.

-

30th April 2008, 08:53 PM #7

Renovator

Renovator

- Join Date

- Apr 2008

- Location

- Brisbane

- Posts

- 7

Without having a great deal of knowledge on the subject.... is there a reason why you can't use 300 blocks the whole way up? Maybe I'm just mis reading your drawing...

-

30th April 2008, 09:09 PM #8

Novice

Novice

- Join Date

- Apr 2008

- Location

- QLD

- Posts

- 16

300mm blocks cost about a $1.50 more than the 200mm ones so considering i will probably need 700-800 blocks thats i big difference in price.

Also the core fill will be a lot more & that isn't cheap either.

-

1st May 2008, 01:06 AM #9

If you lay the sheet down, place a straight edge at 120, scribe the sheet a couple of times with the tip of a trowel, then place straight edge under scribe that the sheet will snap perfect down the scribe.I usually lay the 300s then place cement sheet (3.5mm) ripped down to 120 mm wide with a grinder on the back third of the block then lay the 200s on top of the 300s in line with the face so that the back of the block sits on the cement sheet with a thin layer of mortar and it caps off the rest of the 300 block

If you lay the sheet down, place a straight edge at 120, scribe the sheet a couple of times with the tip of a trowel, then place straight edge under scribe that the sheet will snap perfect down the scribe.I usually lay the 300s then place cement sheet (3.5mm) ripped down to 120 mm wide with a grinder on the back third of the block then lay the 200s on top of the 300s in line with the face so that the back of the block sits on the cement sheet with a thin layer of mortar and it caps off the rest of the 300 block

Great idea, Ive only ever laid any one thickness to the top. Ill mention it to the Site manager next time I do one. c2=a2+b2;

c2=a2+b2;

When buildings made with lime are subjected to small movements thay are more likely to develop many fine cracks than the individual large cracks which occur in stiffer cement-bound buildings. Water penetration can dissolve the 'free' lime and transport it. As the water evaporates, this lime is deposited and begins to heal the cracks. This process is called autogenous healing.

-

1st May 2008, 06:42 PM #10

Novice

Novice

- Join Date

- Apr 2008

- Location

- QLD

- Posts

- 16

Yeah its great the info you come across on forums, exactly what i was after.

-

1st May 2008, 11:19 PM #11

Had the same design retaining wall built, brickies ran a row of normal bricks along the back edge where the gap is, this worked fine!

-

2nd May 2008, 08:25 PM #12

Novice

Novice

- Join Date

- Apr 2008

- Location

- QLD

- Posts

- 16

Normal bricks ?

Where i live 200x400mm besser bricks are the norm.

-

3rd May 2008, 10:18 PM #13

HMM - I thought you had to leave the 300mm blocks open at the top for the pour. 1) so the cores can be rodded (Mortar pushed around and compacted) and 2) a nice head of grout indicates the lower blocks are filled.

-

4th May 2008, 07:45 PM #14

Intermediate Member

Intermediate Member

- Join Date

- Aug 2007

- Location

- devonport

- Posts

- 26

The top of the wall is still open above the 200's and when u drop the full length y-12 bar down after the core fill you rod it up and down as u place it in the core and with an 1800 head height of core fill above the 300,s I will personally guarantee there will not be a void in the 300's , cheers

-

4th May 2008, 07:57 PM #15

Similar Threads

-

Core Fill mix and advice please

By GAM in forum BRICKWORKReplies: 13Last Post: 20th April 2008, 08:11 PM -

Rendering a Besser Block Wall

By srohara in forum RENDERINGReplies: 9Last Post: 27th October 2007, 12:17 AM -

Do I Fill Cavity In Concrete Block Up To Floor Level Help?

By billzgolf in forum CONCRETINGReplies: 4Last Post: 28th July 2006, 07:10 PM -

Fill In Large Hole in Wall

By nesbit in forum BRICKWORK, CONCRETING, PAVING, RENDERING, etcReplies: 2Last Post: 10th May 2006, 07:59 PM

Reply With Quote

Reply With Quote

Bookmarks