Results 1 to 15 of 16

Thread: Timber Over Concrete Stairs?

-

12th June 2007, 08:24 PM #1

Timber Over Concrete Stairs?

Timber Over Concrete Stairs?

Hi All

I am after a few ideas from our professional floor guys in regard to 280 x 32 spotted gum over an old set of concrete stairs

I have chiselled most of the slate of and started putting the 15mm CD ply on glueing and screwing with bostick ultraset as previously suggested on here

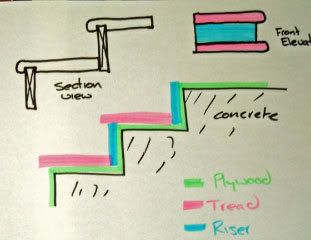

This picture shows how one side hangs over and the other butts up

The Kite landing will have to stay due to head room between it and the ceiling .....Would you laminate up a series of treads to cover this area out of the 280 x 32 tread material if so how would you join them and what glue is best for this... The curves in the two bottom steps will be squared up which will mean the bottom step will need to be mitred is this usually done first and dowelled or biscuited then fitted?

As you can see below one side butts against the wall the side hangs over

so you will see the end of the riser and the tread... I was thinking the tread would go out further to allow for the fact the end will need to be shaped the same as the front

This is how i take its done if both sides are butting into walls or stringers..

What i am after is how to stop the riser and run the tread past as per front elev without having a scrappy end view.... I will run a bead under the tread and back of riser to conceal the plywood once finsihed

Thanks in advance

UteMad

One last thing once the plywood is done what sort of time estimate would you put on installing the treads and risers based on i am a chippy with all necessary tools and a new nailbag (something us chippys don't like cause the old ones always better and looks like you've been around a bit)

-

17th June 2007, 09:35 PM #2

Come on guys !!!

I am now considering putting a fake stringer down the open side to save the head ache but still after the landing and wrap around tread tips

Cheers utemad

-

24th June 2007, 07:25 PM #3

-

25th June 2007, 03:13 PM #4

Nearly finished

Nearly finished

- Join Date

- Jan 2007

- Location

- Sydney

- Posts

- 86

Sorry - but I'm struggling to offer any suggestions for you on this one!

What are you referring to as a "scrappy end view"? Is it the rebate in the tread you're making for the riser? If so then stop the rebate before the end of the tread (square the end of the routed rebate up with a chisel so the riser fits neatly.)

Is it the end grain you're concerned about? If so then the stringer is about the only fix for that.

For the landing you will need to join the boards using something similar to a "tongue and groove" board, or perhaps a simple half rebate, or maybe biscuit join them. For what adhesive to use have a look at what adhesive is used for the imitation timber floorboard packs. I suspect it would be something similar to Liquid Nails.

For the bottom step being mitred - biscuit join will give you the strongest joint. And yes it will need to be done prior to putting the boards in position.

To prevent the mitre joint and the joint between the boards on the landing from opening up as the timber shrinks you will need to allow for expansion somewhere.

Hope this is some help, and perhaps jogs some other members into a response!

-

25th June 2007, 06:00 PM #5

Cheers Loki429

The Prob i have is when i last asked before i removed the slate i was told to run the riser down the back of the tread which is fine when both ends are covered with a stringer cause it won't be seen but when one end is open then the end will be seen and the riser should be seen to be sitting on the tread and the tread should poke out further than the riser which all makes it a lot harder to assemble and makes the treads a lot wider ... I will also have to run a bead all the way down the back of the riser and base of the tread to hide the plywood...

The bead is no prob its the method of how best to assemble the stairs and with the previous tips i was told to start at the top so as not to walk on them and work my way down which i now can't see working if the treads need to go under the risers...

The glue to fix it all down is sweet ( bostik ultraset ) its the glue for laminating the treads and landings i was after...

Thanks for your reply it might get a few others started....

Cheers Utemad

-

25th June 2007, 07:54 PM #6

Utemad, I feel your pain, just looking for a small bit of constructive advice and not a lot is forth coming.

Often, when your there looking at and touching the actual job the ideas come thick and fast. However, even though you have provided great pics it's still hard to come up with good ideas.

So, in the mean time, here are some pics of a set of stairs we recently worked on and I thought the guy did a better than reasonable job of making them a little different than the norm.

The idea was to have the boards continue to run in the same direction as the flooring up-stairs and as you can see he used the one board flowing down over several steps to enhance that effect. (Although, most of that was lost when the boards were stained at the owners say-so )

)

There is no bull-nose or over hang on the treads, which also looked pretty cool.

Anyway, maybe these few pics will offer some sort of inspiration, as you continue to tackle what is quite a worthwhile challenge.

Good luck.

P.S. Any laminating could be done with PVA glue, just as you would for a table glue-up.

<a href="http://picasaweb.google.com/clintfudgefloorsanding/FloorPedersons/photo#5053604988039347730"><img src="http://lh3.google.com/image/clintfudgefloorsanding/RiIC9iM6PhI/AAAAAAAAIT8/2h_7IgivmeY/s288/Floor%40Pederson%20009.jpg" /></a>

<a href="http://picasaweb.google.com/clintfudgefloorsanding/FloorPedersons/photo#5053605439010913826"><img src="http://lh4.google.com/image/clintfudgefloorsanding/RiIDXyM6PiI/AAAAAAAAIUE/g801bmo7UaI/s288/Floor%40Pederson%20010.jpg" /></a>

<a href="http://picasaweb.google.com/clintfudgefloorsanding/FloorPedersons/photo#5053605937227120178"><img src="http://lh4.google.com/image/clintfudgefloorsanding/RiID0yM6PjI/AAAAAAAAIUM/kH94_erafhQ/s288/Floor%40Pederson%20011.jpg" /></a>

<a href="http://picasaweb.google.com/clintfudgefloorsanding/FloorPedersons/photo#5053635293328589266"><img src="http://lh3.google.com/image/clintfudgefloorsanding/RiIehiM6QdI/AAAAAAAAIbc/VB_vgstkYC8/s288/Floor%40Pederson%20084.jpg" /></a>

<a href="http://picasaweb.google.com/clintfudgefloorsanding/FloorPedersons/photo#5053643883263181538"><img src="http://lh3.google.com/image/clintfudgefloorsanding/RiImViM6QuI/AAAAAAAAIdk/YxQqu4cHaM4/s288/Floor%40Pederson%20101.jpg" /></a>

-

25th June 2007, 08:11 PM #7

TIMBER FLOOR CONTRACTOR

TIMBER FLOOR CONTRACTOR

- Join Date

- May 2006

- Location

- sydney

- Age

- 65

- Posts

- 346

Hi utemad, everything looks good so far. When i do what you are doing, i calculate how many boards will be needed to cover a tread and work out how many are needed for a rise. i then will glue up long lengths of flooring together with clamps and then when the glue is dry , i slice off lengths ready to be installed. I do this because it is easer to build the treads and riser off the work piece rather than try to fit board for board on the tread and the same for sisers. You can use ultraset as the glue to laminate the boards together, however there is a polyurathane glue that dries clear that the cabinate makers use. Avail from mitre 10 . I make up widder blanks fr the landings and cut all the treads , risers and landings to shape as needed. you should not have to use a bead.

Overhang your tread over the riser only about 5-10mm when using 19mm material, it looks better. I have seen some sheet over the string with plaster board and i have also made a fake stringer to cover the outside. If you are going to use timber on the outside then build the stairs first and then trace the profile onto a long sheet of 3mm mdf and then transfer on to your timber string to be cut. Hope this helps

-

25th June 2007, 08:17 PM #8

Hi Dusty

Thanks for your reply... I see what you mean about after its stained... He could have almost got away with face ply for the landing and other than the surface hardness you'd have been hard pressed to tell visually...

Yeah its hard i was hoping to get a bit of info from guys who do it for a crust like i do decking etc... But not so lucky as yet... The floor is all laid 130mm T&G spotted gum Select grade and it looks fine just can't get it sanded til i do the stairs ..... I have plenty else there to do but treads will take 1 week to get so would rather get them sooner thaan later... Also 280 x 32 is the bigggest i can ge and with a nosing i need more like 310mm and if i turn it around to cover risers more like 350mm so they would need to all be lami up first

cheer utemad

-

25th June 2007, 08:23 PM #9

TIMBER FLOOR CONTRACTOR

TIMBER FLOOR CONTRACTOR

- Join Date

- May 2006

- Location

- sydney

- Age

- 65

- Posts

- 346

It is best that you go and buy the timber now and leave it sit on site while you are doing all your prep work as it will climatise it and reduce shrinkage. also sand the treads and risers first before you install them. that way you will only need to clean them up with a light sand using 120grit after they are installed. Select flat straight boards for your project.

-

25th June 2007, 08:28 PM #10

Hi Larry

Are we still talking about using 32mm thick for treads and 19mm for riser as before when we discussed plywooding it first?

As per the drawing i did above with the highlighter is that how i lay the treads and risers or are we saying to sit the riser on top of the tread and if so do i have to route the top of the tread as well as the base of the front ?

What I am concrened about is where the open side has no stringer the nosing profile has to be applied to the end of the tread aswell...

This means the riser needs to stop short atleast the amonut of the nosing profile..

When you look from the open side it wont look good if the riser is seen to be behind the tread so i would have to return the tread around to atleast level with the back of the risser

If you want me to do a sketch i can if it helps

Its starting to sound simpler to put a full fake stringer down the open side to cover all the ends if i cant work this out

Thanks for all your help so far and the bostik works a treat used 2 boxs so far

cheers utemad

-

25th June 2007, 09:06 PM #11

TIMBER FLOOR CONTRACTOR

TIMBER FLOOR CONTRACTOR

- Join Date

- May 2006

- Location

- sydney

- Age

- 65

- Posts

- 346

Sorry bro i forgot about us talking about it before. I understand your situatuion with the overhang over the stringer. Th tread only needs to over hang the stringer. No need to o/hang the riser. Thye best thing to do is , before you assemble the treads and the risers, get some 3mm mdf and pin it on to the side of your stairs. The mdf needs to be as long as the flight of stairs . What you are going to do is get a profile of the stairs and risers so that later you can cut out the stringer and attach it to the side of the flight of stairs. Apply all the ply to treads and risers first

1/ First thing you do is pin up the mdf

2/ Scribe along the mdf where it meets the each ply tread base .

3/ Scribe along the mdf where it meets each ply riser base ,

This way you will be able to o/hang the tread over the stringer and the riser will overhang the stringer as well ,but you will cut the riser flush with the stringer. You will then transfer the profile from the mdf to your stringer material, When it is installed it should fit behind all treads and risers. The end grain of the riser will be exposed, so all you do is install a 25mm wide trim down the risers and then underr the tread then down the riser then under the tread and so on.

As far as the install method of tread and riser. You can do it the way you are doing it now, or you can install the tread first and then sit the riser on top of the tread. You dond need to rebate the tread at the bottom, it all sits nice and flush naturally. If you are acurate enough, you can also not rebate the underside of the tread. Just sit the tread on top of the riser.ONLY IF YOU ARE ACURATE in your measurements>

-

21st October 2007, 05:19 PM #12

Jobs All Done

Jobs All Done

Jobs all done and i thought it was about time to post the finished pics for all to see

It all came together nicely in the end....Larry got the job of sanding and finishing the floor and stairs and as all can see i think it came up a treat..

We still have to suspend a sheet of glass down the open side to close it off which will hopefully be in by christmas

Thanks Larry for your help with the stairs

cheers Utemad

-

21st October 2007, 05:34 PM #13

Nearly finished

Nearly finished

- Join Date

- Jan 2007

- Location

- Sydney

- Posts

- 86

Wow - looks great!

One question - how did you attach the timber to the plywood underneath? I can't see any fixings in the photos...

-

21st October 2007, 06:23 PM #14

Fixed the timber to the ply with bostik ultra set and 4 x 1 1/4 bullet nails for the treads and 2 x 25mm bullets for the risers.... Nails are only to position til glue sets so you can keep working your way up walking on them

cheers utemad

-

21st October 2007, 06:51 PM #15

TIMBER FLOOR CONTRACTOR

TIMBER FLOOR CONTRACTOR

- Join Date

- May 2006

- Location

- sydney

- Age

- 65

- Posts

- 346

Similar Threads

-

deck ontop of concrete steps

By oricenap in forum CONCRETINGReplies: 2Last Post: 25th June 2007, 09:25 PM -

Painting Concrete & Timber Floors

By versetcat in forum PAINTINGReplies: 3Last Post: 5th October 2006, 02:15 AM -

Deceptive timber

By Suresh in forum HAVE YOUR SAYReplies: 1Last Post: 17th September 2005, 12:42 AM

Reply With Quote

Reply With Quote

Bookmarks