Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 31 to 45 of 108

Thread: A ? about roof flashing

-

13th February 2007, 06:53 PM #31

I was following the builder’s orders and I’ll admit that there was no engineer consulted at the time, however I feel that if there was, then he would have approved a way to install the flashings as a retrofit. I’ve installed a few steel engineered columns and a common procedure is to place a small packer in the centre of the column and grout the base in afterwards with either a non-shrink grout or s 3:1 sharp sand cement mix. Perhaps he would have specified that.

I’ve also retro fitted a steel corner structure under a two story double brick terrace house in Paddington. The whole lower storey Southern elevation was removed as well as the return on the Western side. From memory it would have been over three metres South and five or six metres North. After installing needles on acrow props, we removed the lower brickwork and installed a heavy steel portal frame that increased the ground floor area by a metre to the West and about three metres to the South from memory. We installed cedar rafters and we flashed it with lead going up under the old cavity above. The bricklayers came along and bricked up on top of the flashing, sliding their bricks under the old wall and they pointed up the gap by pushing mud into the joint with pointing trowels and plugging chisels. Then we installed a glass roof on top of the rafters. The structure was designed by an engineer who certified it on completion. There have been numerous other occasions where I’ve installed engineered beams up to six metres long under an existing wall in the same manner. They have all been approved, but of course your engineers may recommend to tear the wall down and re-build it. I’d recommend that you get another engineer then, because I’m sure that I could find one that would allow you to grout the bricks in. Regardless of which way would have been recommended, the wall simply could not stay the way it was with a saw-cut flashing.

It leaked and therefore it was dodgy. There was no other way of fixing it to the customer’s satisfaction than to install a trayed flashing as it has been done for hundreds of years.

Nevertheless I can sleep well at night, because as you say, the wall is tied back to the framework and the mud was well packed in along the length. I was working as a carpenter at the time and I had no licence at all. I’ve never done an apprenticeship, and I was yet to sit for the builder’s course at that time. I’ll agree that it may be dodgy to perform the work without engineer’s approval, but I won’t agree that it couldn’t be done that way, and I'm certain that that wall won't go anywhere.

On the other hand, if I built something like this then I may not be able to sleep as well. Especially if you did use silicone in the joint. If you showed that to an engineer, I reckon that he’d either have a fit, or he’d have a fit of laughter thinking it was a joke, and I’m not talking about my mate Humpty. If you recommend a minimum of 40mm, then that drawing of yours looks like you’ve cut 50mm into a metric modular brick of 90X190X290 and filled it with silicone. Of course if it is tied back as well then it may be alright and you may find an engineer that would approve it, but personally I don’t think any engineer would allow you to go past the centre of gravity of the wall.

I’d be interested in finding out how deep they’d allow you to cut if you could ask them, and what their opinions are on the countless buildings around the place where old brickwork has been grouted from underneath on top of a flashing. Of course they may just refuse to take on a job like that and leave it to someone else. But I can assure you that there’s many examples in Sydney of new shopfronts with large clear openings being installed under preserved historic buildings. Thanks to you too. It’s interesting. BTW don’t take Humpty too seriously. It’s just the internet and I’m just trying to rev you up bricksy.

-

13th February 2007, 07:35 PM #32

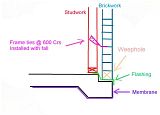

I can't find a detail on the net, so I've sketched up a typical brick veneer set up. Click to enlarge: -

You'll notice that the frame ties should be installed on an angle to prevent any water running down the inside of the outside skin, from getting to the inside studwork. Bricklayers must hose any spilled mud out through the weep holes to prevent it building up and conducting water inside. The weep holes should stay clear for future water penetration.

I wonder what stops the bricks from sliding around on the flashing since your engineers don't like that sort of thing?

-

13th February 2007, 08:33 PM #33

End of discussion i hope.

"sub-standard building practices""someone who calls themselves "bricks" and who has attended a builder's licensing class doesn't understand the basic limitations of bricks."It’s a simple case of physics, capillary action, and the laws of gravity..don't expect me to allow dodgy advice to go unanswered

End of discussion i hope.

"sub-standard building practices""someone who calls themselves "bricks" and who has attended a builder's licensing class doesn't understand the basic limitations of bricks."It’s a simple case of physics, capillary action, and the laws of gravity..don't expect me to allow dodgy advice to go unanswered

The Engineer from the Master Builders got back to me.You have a problem admitting when you’re wrong

http://www.australinsulation-vic.com.au/PDF%20Files/Econodeck%20Install%20Guide.pdf (PDF file takes a while to down load.)

http://www.tufftile.com.au/technical.html

http://www.hamiltonroofing.com.au/glossary.htm

http://www.stramit.com.au/images/techmanuals/blank.jpg (PDF)

http://www.harmonyrooftiles.com.au/m...oreword.html&0 (section 5.3)

http://www.bluescopesteel.com.au/ind...F600C04FCF6B8F (PDF)

The engineer gave me these links, take time to read the pdf's,

Bluescope steel and strammit I belive are at least nation wide manufactures of roofing products in this great country

Your cavity tray type x is Brittish and is not supplied here.

http://www.cavitytrays.co.uk/damp_products.php?id=typex

It is a preformed tray,

IMO it isnt designed for post fit, rather to be fitted at the time of construction as the dialouge says. ( with the bricks)

The others i have been told are well respected roofing comanies from east to west coast of this country.

I HAVE NOT ONCE INSULTED YOU OR MADE REFERENCE TO YOUR OBVIOUS ARROGANCE IN RELATION TO A SKILL WITH WHICH I MAKE MY LIVELY HOOD. YOU HAVE REPAETEDLY INSULTED ME AND ANYONE ESLE WHO DEOSNT AGREE WITH YOU.

EAT YOUR WORDS AS YOU SAID YOU WOULD

I AM DOING THE SAME REASARCH FOR PEX PIPE ALSO AND WILL GET BACK TO YOU SOON

ANYONE WHO CARES CLICK THE LINK AND SEE FOR YOUR SELF.

I spent A total of 4 years in my apprenticship, 2 years doing my master plumbers, and 4 years doing my master builders. I was trained by men who did not put up with lazy apprentices, who threw tools and punches if it wasnt done right, most of them 40 years or older. I spent over 33% of my life leaning about this stuff. 10 years at school, All while working stupid hours, trying to start/ run a business, and paying for it out my own back pocket. I know what im doing and if i dont know, i dont do it.Last edited by bricks; 13th February 2007 at 09:31 PM. Reason: felt like it.

If you dont play it, it's not an instrument!

-

13th February 2007, 11:28 PM #34

Bricks,

at the risk of getting caught in the cross-fire I'd like to ask a couple of questions in order to hopefully clarify things.

1) Are you aware that a brick skin is not water proof?

2) Do you realise that the method that John is advocating results in a finished product that is identical to the ideal flashing that would be fitted during construction? ie it's visually and structurally identical.

Given this, then either you didn't explain things clearly to the engineer or they misunderstood.

Re Pex:

Ring Reece or Tradelink in Cairns and ask them if they sell much Pex.

Mick"If you need a machine today and don't buy it,

tomorrow you will have paid for it and not have it."

- Henry Ford 1938

-

14th February 2007, 03:27 AM #35

Calm down bricksy. Whilst I've said that it's amusing watching someone lose their composure, I'd hate to see you blow a brain gasket or have a heart attack over an internet argument.

In case you didn't know, using all caps on the internet is considered shouting and most people don't like others who shout on the internet. You're not only shouting at me but you're shouting at the rest of the forum members as well with your last sentence. Highlighting important text should be done with underlining, emboldening, or italics: -

As far as insults go, it doesn't say anything about that if someone deserves it. The only direct insult I've made toward you so far is this: -# Avoid using all uppercase letters. ALL CAPS LOOKS LIKE SHOUTING TO THE READER! If you are aiming for emphasis and differentiation, use color, bold, italic, _underlines_ or *asterisks* or extra white space. Even if you intend to shout, *never* use uppercase for more than a few words; it's just too hard to read.

http://www.futureustore.com/publicat...etiquette.htmland I gave evidence for my impression of you. Prior to this I hadn't even made an indirect insult on your character. I made a few jokes and I said that installing a saw cut flashing over an internal wall was dodgy and I still stand by that comment. Originally Posted by pawnhead

Originally Posted by pawnhead

It was you who escalated this debate with these comments: -You were quite clearly insinuating that I'm pigheaded and brainless before I had made any attacks on your character. I think you need to develop some more wit and tact if you wish to successfully debate a topic on the internet without losing your temper.

Of course later on I said this: -I'm not insulting you there, and I stand by those comments. I'm sure I could find an engineer who would back me up on that if I wanted to spend the money on a consultation. I emboldened some text because it would concern me if anyone decided to do just that. IMO they would be taking a risk and I certainly wouldn't want to live in a house where the majority of the brickwork overhead was being supported by silicone. Especially if it were in a cyclone area, but even if it weren't I'd still be dreading a one in one hundred year storm. If you can find an engineer who would approve that drawing of yours then I'd expect you to give his name and I'd expect you to give some proof. It's quite easy for you to say that some anonymous engineer is discrediting my methods of installing flashings whilst approving yours. Does he exist bricksy? If he does then give me the opportunity to speak to him. Originally Posted by pawnhead

Originally Posted by pawnhead

Apart from that there were some lighthearted jokes from me but that's par for the course on these forums and it's nothing to loose your temper over, for example, in this thread Eddie Jones said this to me : -To which I responded: - Originally Posted by Eddie Jones

Itís important to retain your composure bricksy.

Originally Posted by Eddie Jones

Itís important to retain your composure bricksy. Originally Posted by pawnhead

Originally Posted by pawnhead

Now.

Iíll stand by my words and Iíll eat them if youíve come up with any proof. I didn't expect you to find any, but I donít mind admitting when Iím wrong. Youíll also recall that I said it wouldnít stop me building my walls so they were waterproof, and I wouldnít guarantee any wall with a sawcut flashing. I think youíd be foolhardy to, given my own experience in the past. However itís quite late now and Iíve yet to go through those links. Iíve got a lot on tomorrow so donít expect a speedy reply but I will give one.

Meanwhile take a chill pill and don't yell and don't get too upset over anything. You'll only make yourself look foolish. You can insult me all you want though if you need to blow off some steam.

-

14th February 2007, 05:34 PM #36

The above pages at a guess Are approximately 600 pages of technical data, illustrations and installation method "how to's" for steel and tiled roofs. Uploaded to internet by leaders in roofing products, technology and installation systems in this country.

Any one who wishes to install, alter, flash, fix, renovate, extend etc and in the process do their own roofing would be advised by me to read the pdf's available on the links, they are the highest quality manuals I have seen on the issue.

I am through argueing, for this one reason,

I printed and gave a copy of pawny's method to a roofing plumber who works with me, the end result was that he laughed so hard Ice coffee came out his nose, thats how ridiculous he thought it was. ( dinkum)

My drawing was a crude technical drawing, indicative only do not use it, it's not to scale.

Read the PDF's

If you take all the bricks out of a wall in any sequence and put them back again using any combination of in's and outs', My building liscence tells me that wall is now structrually unsafe.

Read the pdf's

Yes journey man I realise both those things, I would advise you to read the Pdf's available, it will take you hours. The method outlined in all of them Is what i believe to be Standard Industry Practice regarding flashings to adjoining walls. From my past expirence, this method works.

I have not said that pawnys method will not work, in fact i agree that it would be better. You are correct in saying pawnys method is used when building a wall during construction of the wall. Existing house, new ball game, You cant take bricks out of walls without knowing what your doing, inserting lintel blocks, ties, props, etc. I dont belive that pawnys method is possible because of the danger of removing bricks, And there is a suitable alternative which happens to be also standard industry practice.

Read the pdf.

The average Joe Homeowner should not remove bricks from walls, let alone effectively a whole corse. The method outlined in the PDF should be looked at as a do-able option, no bricks removed. You dont even have to follow the corse line just cut a straight line straight into the block if you like.

Read the pdf's

I spent my time reasarching this through various agencies and organizations the least you can do is............................

Read the PDF'S

If you dont play it, it's not an instrument!

If you dont play it, it's not an instrument!

-

14th February 2007, 07:57 PM #37

Bricks I suggest you chill out mate.

As a fellow South Aussie and a former plumber I am embarrassed by your behaviour since you have joined this forum. What you should realise is that regulations from the eastern states are for the most part completely foreign from those we work under in SA. One size does not fit all!

To set your self up as a know-all to end-all in this forum, over riding the numerous years of experience of other members who are more experienced in their local regulations, I can only put down to your impetuous youth. You will learn to be flexible with age because slinging matches are only dragging this forum into disrepute.

To put it bluntly if you dont like it here mate and cant get along with other members feel free to bugger off.Jack

-

14th February 2007, 08:09 PM #38

Sorry to all those who posted, read this, I ll pul my head in.

The reason im annoyed is because basically pawny's method is a theroretically better method, and in practice would work more effectively. My method however I have proved is also correct, the files are located above, they are comprehensive manuals on all types of roof installation from highly respected organizations.

I have downloaded and saved them for my reference and advise anyone who is interested to do the same, they cover everything.

To pawny, if you find anything post it, really, the god fearing public deserve to have a choice, I don't appreciate the insults and I apologize should i have caused offence to you directly,The truth is i find it hard to decypher sarcasm from, insults and vice a versa, Im not familiar with the forum protocols, or unwritten laws, perhaps you have misunderstood me. Im not saying your wrong, just saying theres another way to do it.

I am considering this thread done with, ill not post here again unless nessecary.

I aplogise to anyone who has to sift through all this rubbish to find any usefull info at all.Last edited by bricks; 14th February 2007 at 09:28 PM. Reason: Add appology

If you dont play it, it's not an instrument!

-

16th February 2007, 04:01 PM #39

Oh dear..Ok I didn't expect to see an argument over it, sorry it sparked one..

I did do some reading on the net (and also just checked the links privided) and did see alot about the staggered way by cutting in the brick mortar, alot about the 1.5mtr lengths but hubby and I have also done alot of driving around our area, and checked alot of the homes out and their is some of both methods here and heaps of none staggered in our area..I am in W.Australia..

The roof plumber I was going to hire was not going to remove any bricks, but I can definatly see that it should be done during the brick in stages IMO....But being a first time owner builder no one told us and you learn alot along the way..I am not sure if he was going to stagger it or what but he only quoted us on lead flashing fitted...

Thanks for all your input...After I read this out to hubby, I think we are going to get some quotes and get a roofing plumber in to do it..

That harmony web site shows using 2 different types of flashing in the same join, that wasn't something we thought had to be done (but I had seen it on the net before)....

Thanks again

-

16th February 2007, 04:32 PM #40

-

16th February 2007, 04:44 PM #41

LOL ..Thanks...I must admit I don't mind a good argument when you feel passionate about the subject

-

17th February 2007, 02:35 PM #42

Due to various PM's from both sides of the fence, often with the blind fury associated with neo-religious cult leaders and politicians, i will post one last time on this topic.

Pawny now has a flashing method, and a referance material to go with it, I have also learned a new technique and its intended applications. Both methods will work, but as with everything need to be applied in the right situation for the right application. We have agreed on this in PM.

We both have gained knowledge which we can apply where we see fit.

Eg. if your existing wall leaks very badly IMO the saw cut method is not the way to go. If you use the brick removal method IMO it would be because the structural dangers of a badly leaking wall far out weigh the dangers of removing / replacing bricks.

I will not be using the removal method, in my opinion it should be done by a builder who specialises in this type of work. I would refer customers to one of these builders should I think it was nessecary. Pawny used this method under instruction of a builder, who then guaranteed the wall, theres nothing wrong with that.

The PDF's are good, best ive seen anywhere, use them. IMO if you cant interpret or still have questions about basic roof flashing after reading those pages, call a roofer.

I do appologize again for my posts during this thread, i have learned alot from your answers, I now understand the forum equivilent of being civilised and corteous to all involved. I also realise the need to be precise in my statements as perhaps mis-interpretation is easier to do when reading a post than in face to face disscussion. I thought by using capitols it would highlight my main points, did'nt realise that was shouting and abusive.If you dont play it, it's not an instrument!

-

17th February 2007, 04:38 PM #43

Bricksie,

it's not always easy to "back down" but, in the end people respect you far more for it. Welcome to the forums mate!

Mick"If you need a machine today and don't buy it,

tomorrow you will have paid for it and not have it."

- Henry Ford 1938

-

17th February 2007, 09:02 PM #44

-

19th February 2007, 02:33 PM #45

Gees talk about being passionate about flashing.

Pawnhead, Ive been in the bricklaying trade for 36 odd years and have never seen flashing done as per you picture. No chippie that I know puts flashing under the bottom plate and the flashing in the brickwork is 1 course too low, when the garden or path is put against house it would breach the flashing.

Wall ties havent bean done that fashion in Vic for at least 25 years since the introduction of sisalation.

Al

Similar Threads

-

pergola roof over tile house roof

By Lbudgie in forum PERGOAS, GAZEBOS, STROMBELLAS & ROTUNDASReplies: 3Last Post: 24th March 2006, 05:58 PM -

Long span garage roof deck, more thoughts

By Wildman in forum DECKINGReplies: 4Last Post: 29th September 2004, 08:00 PM

Reply With Quote

Reply With Quote

Bookmarks