Thanks: 0

Thanks: 0

Likes: 0

Likes: 0

Needs Pictures: 0

Needs Pictures: 0

Picture(s) thanks: 0

Picture(s) thanks: 0

Results 16 to 30 of 34

Thread: pergola fascia fixing - newbie

-

11th December 2007, 11:18 AM #16

What you are effectively doing (assuming you put a roof on it, which I gather is the intention) is altering the roof load width as it applies to the existing wall. If it's a truss roof, the existing roof load width is equal to half the length of the sloping part of the truss between the wall and the ridge plus the overhang. If it's a framed roof, well who knows without actually looking at it.

When you add this 'pergola' - which is really a verandah because a pergola doesn't have a roof - you are increasing the roof load width on the existing wall by 1/2 the length of your verandah rafters - in your case 1500mm. So the question is, does your existing frame support this new load width? Perhaps it does, perhaps it does not. If it's double brick, you're OK. If it's timber frame then you might be pushing the limit.

But they probably don't mention things like that in the Mitre 10 brochure "I don't practice what I preach because I'm not the kind of person I'm preaching to."

"I don't practice what I preach because I'm not the kind of person I'm preaching to."

-

11th December 2007, 11:21 AM #17

I know sod all about brick houses. I presume if it was brick veneer, then what you say is correct, in which case the rafters would be a better fixing point perhaps? Not sure.I thought the external wall wasn't structural either.

I know sod all about brick houses. I presume if it was brick veneer, then what you say is correct, in which case the rafters would be a better fixing point perhaps? Not sure.I thought the external wall wasn't structural either.

For timber frame, the wall has to carry the weight either way, I just feel it would be a better fixing than the ends of the rafters. It's only a layman's opinion though."I don't practice what I preach because I'm not the kind of person I'm preaching to."

-

11th December 2007, 11:36 AM #18

good post barned01 - a stout design. a consideration is the concrete-set timber post will be a durability issue because the conc shrinks and leaves a gap around the post which creates a water trap. you must allow for suitable drainage at the bottom of the post otherwise the rot will set in at the base of your posts. alternatively you can use some post-anchors.

i think you should be able to enlarge the fence footing without disturbing the existing concrete as long as it is not 'crumbly' - just dig around and enlarge, also go deeper underneath - it will pay to put some large gluts under the bottom rail of the fence to keep it in place while the new footing goes off & you dig the soil back in. be sure to tamp the earth at the base of the footing well with something heavy, to minimise movement. maybe even jack the fence up slightly to allow for settling.

something else to consider - if you are fixing your posts to the fence then the rafter joint to rafter-support beam or rafter to house-rafter or truss must allow for some movement or it will resolve itself along the fenceline by pulling/pushing it toward/away from the house. your situation will determine whether this is an issue or not - i guess it depends on how much of a feature your fence is

silentc raises some good points about fixing to the wall & roof frame - certainly the code demands the span of the verandah be considered when designing the wall. it probably wouldnt be an issue for the wall itself - the issue will arise with openings in the wall. as the roof-frame is supported above openings by lintels, this will be your area of biggest concern; considering this and the above, you may be better off overall building a free standing structure that doesn't attach to the house or the fence.

r's brynk"Man got the opposable thumb - woman got four opposable fingers." - Rowdy

-

11th December 2007, 11:48 AM #19

I originally said "if you have windows or doors under the new roof" but I took it out, because even bearers are subject to RLW calculations. Again, if it's double brick, it's probably moot.the issue will arise with openings in the wall

I originally said "if you have windows or doors under the new roof" but I took it out, because even bearers are subject to RLW calculations. Again, if it's double brick, it's probably moot.the issue will arise with openings in the wall

However if the existing RLW is within 1500mm of the maximum RLW used to determine any part of the structure, you could put the structure under-spec by adding a verandah roof to it. The point is, people do these things without considering the wider implications."I don't practice what I preach because I'm not the kind of person I'm preaching to."

-

11th December 2007, 12:07 PM #20

Just some extra piece of info regarding the proposal.

Soil is heavy clay, i can go wider to 450*450 post footing and go a little deeper to maybe 400 around the area the concrete base already is. Posts will be 90*90 treated pine at 2.4mt spacing. I specifically do not want to take out the existing colourbond posts and start from scratch since i have developped landscaping plants on the other side and in another area there is stencil concrete driveway. Too much work for my liking but still thanks for the idea.

The beams will be 190*45 and the rafters and ledger beam that attaches to the fascia with the use of a angled rafter bracket(i seen them at bunnings dont know the exact name) will be 140*45. Wishing to use laserlite on top of the pitched roof. There is a current 45mm gap between the fascia and the end of the rafter in the roof, which that bracket would fix by reinforcing the rafter so i can attach a ledger beam onto it. The brackets I assume would go on every rafter every 600mm i think. Also house is double brick.

The current colourbond fence islocated on the boundary so i know i must get a permit regardless which is another issue. Area is melbourne Hume city council.

Just wondering shall i use rapid set concrete bags or shall i make my own concrete mixture etc? Also as for the post brackets, since i cant fully deep in some areas, would it be wiser to concrete the hole and then fix different brakets (the ones that dont have a stirrup) onto the concrete with blue tip concrete bolts (not dynabolts bad experience). I know that the bottom of the post shall be protected from rust but these brackets elevate the post slightly which avoids that problem.

Hope thats some more info.Last edited by ozizu; 11th December 2007 at 12:10 PM. Reason: forgot info

-

11th December 2007, 12:57 PM #21

Good oh, ignore everything I've said then. Except the bit about the pop-rivets - that's just stupidAlso house is double brick

Good oh, ignore everything I've said then. Except the bit about the pop-rivets - that's just stupidAlso house is double brick "I don't practice what I preach because I'm not the kind of person I'm preaching to."

"I don't practice what I preach because I'm not the kind of person I'm preaching to."

-

11th December 2007, 01:12 PM #22

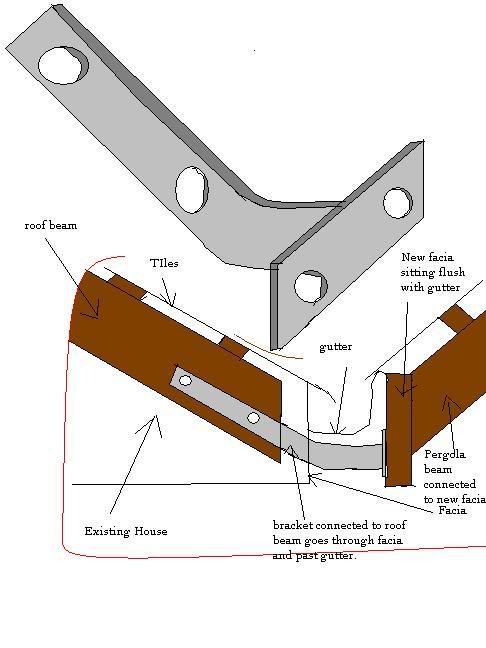

that 45mm gap between facia and rafter is the same gap i had, which just so happened to coincide with a statndard peice of 45mm thick pine that you see on all the building sites. if you can get that in thereand use those brackets to attach to the rafter and the peice of wood, then there is your reinforcing of the facia (i will see if i have a 3d picture of what i mean.....)

i pretty much replicated that for every rafter i came to in the roof which i think was 7 in total, the theory being the load of the pergola would then be spread along all of them...note this was by far and a way the worst job of building the pergola.

if you didn't want to put the piece of wood behind the facia, there is another style of bracket bunnings have (although the version from olympic industries is better as it is sooooo much more longer) that allows you to put a new facia onto the house just past your gutters. this is an easier bracket to install and you don't have to fiddle around getting that piece of wood behind your facia....but then you have 2 facias and a void to fill between them, but that is how most pergolas are constructed if you look at a lot of pergolas already out there

and there is yet another bracket that goes above your structural wall and pops out through your roof, kind of like a stirrup to allow you to create a pergola that sits slightly above the existing roof but i can't remember how that one looks.

I personally am against rapid set concrete especially for something structural. if it was good stuff why wouldn't it just be called standard set concrete and the slow set stuff be taken out of the market completely.

Concrete cures over the space of several months and gets harder with each passing month. To have it set in 15 minutes plays against my understanding of concrete. sure it is harder to make everything square while you wait for it to set, but you feel good knowing you didn't use the 15 minute stuff

And if you go to the same section the anchor bolts are in you should find a set of chem set bolts which come with a test tube style system of setting compound.

Drill your hole in the concrete, place tube in hole, screw the bolt int othe hole effectively crushing the tube already inside, wait half an hour and you have a bolt that will be stronger than either a dyna bolt or anka bolt.

ps. Im not a builder but am just drawing on experience when i did mine and my house was brick veneer with truss style roofing.

-

11th December 2007, 02:03 PM #23

Great info barned01. Answered most of my issues well. Definitely now going to not use rapidset concrete. Also the bracket you used from olympic industries, im assuming that wasnt from a bunnings store. The one i seen at bunnings is a pryda bracket for around $10. I have roughly 10-11 rafters to put these brackets on but hey, its better to be safe than sorry.

Im probably made my mind up about the post footing at 450*450 and digging down as far as i can go probably till 400mm. fill with hand made concrete, attach above ground post brackets with the post elevated. I basically got this idea from a chap who done his work http://jaw.iinet.net.au/projects/pergola.html

Even though his backyard is much bigger, there are some similarities with the colourbond fence and green posts and pitched roof. Especially the green lattice he used.

Once again thankyou Barned01

-

11th December 2007, 02:39 PM #24

Your total uplift area on the posts is approx 9m2.

Work out the uplift per post i.e the end posts will have half the uplift load of the internal posts. Don't quote me [ it varies depending upon the designated wind gust speed ] but a 450*450*450 deep pad will cope with around 5m2 uplift.

the founding depth for load should be around 500mm - 800mm depending on the clay type. This is strictly speaking in regards to a house structure etc but I don't know of any 'leeway' in the reg's for a small verandah.

If the roof slope is to the boundary, the gutter has to be inside the fence line.

Termite treatment around the posts.Peter Clarkson

www.ausdesign.com.au

This information is intended to provide general information only.

It does not purport to be a comprehensive advice.

-

11th December 2007, 03:09 PM #25

that facia bracket in the first picture is a piece of 2mm steel about 20cm long and bent to the right angle if you were to buy it from bunnings as you have seen (that pryda bracket you speak of).

This looked woefully underspecced so i just went down to my metal merchant and got a peice of 65mmx3mm (i think...could have been 5mm) thick strap.

i then got a hole cutting firm to punch some holes in it (50 cents a hole) and i welded the facing plate to the front of it.

So in all i ended up with 50 cm long strap with more holes than the bunnings one and also more rigid (by far). And funnily enough i think it came out to be cheaper than buying the equivalent number of straps from bunnings.

the second one (with the slight curve in it and a hole on each end of the facing plate) is the one you gan get from olympic industries...they are about 1.5 metres long at olympic but only around 45cm long at bunnings.

without seeing better pictures, these are the sorts of brackets i think that that person in the link you supplied would have used.

-

11th December 2007, 09:12 PM #26

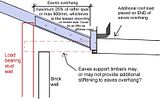

You have to consider all the forces acting on your existing eaves overhang.

barned01's diagrams don't completely address the fact that the eaves overhang is considered as a cantilever, and is usually allowed to be no more than 900mm depending on the specific circumstances. It could be as little as 450mm or less.

There are span tables here which give maximum eaves overhangs, and they don't make allowances for whacking an extra 3 metres of roof framing supported by the end of the eaves overhang.

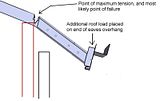

This is what could happen if you're not careful by using a long and strong reinforcement method that cantilevers over and back past the load bearing wall which will eventually carry the loads from your new roof as well as the existing roof:

The existing rafter may already be weakened by a birdsmouth cut out above the load bearing wall, and there could be significant additional tensional stresses applied at the top of the rafter at the same point, which could lead to failure if it's not considered in the design of any stiffening.

-

12th December 2007, 01:35 AM #27

pawnhead:

the stiffening beams i placed in the roof go back past that point of the structural wall and fulcrum point (you can see the size and specifications i used on the first picture on the first page, 45mm thick x 90mm wide x 1.6metres long, although i ended up using 2 metre long beams instead and the wood was standard mgp10 or 15 that you find on a building site rather than F8...whether this was good enough, i guess time will tell).

i did that as because as you alluded to, i looked in the roof and thought that would be the weak point (my rafters had that cutout you speak of also).

so combining that with spreading the load over multiple rafters (connected via the hidden facia beam installed behind the aesthetic tin one) then the load share should have reduced sufficiently and pulled the stress point further inside the roof cavity (again this is using my own logic, i am not a builder, i did not get an engineers report, but my council did approve the plans as i submitted it to them and they do have an engineer on board to assess these things.)

also on one of my corners i did even install that triangulating beam as well using a piece of angle iron i had lying around. Although it wasn't on my council plans, i just did it for my own peace of mind.

but ozizu's is a solid brick home, so i don't know if that luxury exists in this instance of installing a triangulating beam. And i don't know if the external brick facia is considered structural or not to triangulate from that, when i did mine, i took it as it wasn't structural so left it alone.

also notethat those the new facia brackets i mentioned from olympic industries also extend past that fulcrum point which is why i recommended them over the bunnings ones which are a lot shorter and commonly don't extend deep enough into the roof cavity (i think they were 1.5metres long from memory of 5mm thick steel).

-

12th December 2007, 06:37 AM #28

I can see on your second diagram that it's stiffened by an extra piece of timber, and having this treatment on every rafter would be sufficient I'd say (but I'm a builder, not an engineer). I was merely pointing out that this point of weakness must be considered since it hadn't been mentioned anywhere. Those short Bunnings stiffeners wouldn't be up to the task IMO, and neither would those short stirrup type brackets unless there was no eaves overhang or the eaves support timbers form a solid triangle which braces the overhang horizontally back to the load bearing wall. But even in this case, I would at least nail some hoop iron strapping on top of the rafter, extending from the end of the rafter, well past the load bearing wall. This would help take up the additional tension placed on this weak point.

I'm simply saying that this point of weakness must be considered before placing any additional roof loads on the end of an existing eaves overhang.

-

12th December 2007, 08:49 AM #29

I have never seen a pergola atached to the fascia cause significant problems to the rafters. I have however seen facias pulled off. I think barned method is well and truly overdesigned ( i am not an engineer either) For timber facias we generally accept a bugle crew to each rafter end and a joist hanger atached to the existing fascia. No rafter strenghthening required. If i saw something that changed my mind i would reconsider this. As you or all aware building surveyors and inspectors that are pioneers in not accepting tried and true methods become very unpopular quickly (not that we are popular in the first place)

-

12th December 2007, 01:33 PM #30

I agree with that.

Spanline have been attaching Patio roofs to the ends of rafters for the last 18 years with Council approvals and have never lost one yet. Certainly not to metal fascia without some support back to the rafters but fixed certainly through timber fascia to the ends of the rafters as thebuildingsurv says. They have 1,000's of extensions all over Australia.

Reply With Quote

Reply With Quote

Bookmarks